The Art of Light Weight Aluminum Casting: Enhancing Your Skills for Superior Outcomes

Light weight aluminum spreading is a craft that requires precision, patience, and a deep understanding of the methods entailed. As developers and artisans, our search of excellence in aluminum spreading is a trip that calls for devotion and a continual mission for mastery.

Background of Aluminum Casting

Light weight aluminum casting, a procedure with beginnings tracing back centuries, has actually played a significant function in the growth of various industries. The background of aluminum casting go back to the 19th century when it became a pivotal production strategy. The usage of light weight aluminum in casting procedures reinvented industries such as automobile, aerospace, and building and construction because of its lightweight homes and rust resistance.

One of the earliest uses aluminum spreading can be traced to the production of cooking equipment and ornamental items. As innovations in modern technology took place, aluminum spreading broadened its reach to consist of engine elements, architectural components for aircraft, and detailed styles in architectural frameworks. The versatility and flexibility of light weight aluminum casting permitted the development of complex shapes and layouts that were previously unattainable via other manufacturing methods.

Today, light weight aluminum casting proceeds to be a cornerstone of contemporary commercial procedures, enabling the production of facility components with high precision and performance (casting aluminum illinois). Comprehending the historic evolution of light weight aluminum spreading provides useful insights into its long-lasting value and continuous advancement in the industrial landscape

Vital Tools and Equipment

Using specialized devices and tools is important in accomplishing ideal lead to the light weight aluminum spreading procedure. The fundamental tools required for aluminum casting include a crucible for melting the aluminum, a heater to get to the necessary temperatures, and molds to shape the molten steel. Crucibles, typically made of graphite or ceramic products, must stand up to heats to avoid contamination of the light weight aluminum. Heating systems are important for warming the light weight aluminum to its melting factor, normally around 660 degrees Celsius, ensuring it is in a fluid state for spreading. Molds come in various forms, such as sand mold and mildews or die-casting molds, to offer the aluminum its wanted form.

Safety gear is important to stop injuries from the high temperatures involved in the casting procedure. Generally, having the right tools and devices is paramount for achieving high-quality and accurate aluminum spreadings.

Mastering the Casting Refine

Having gotten the important devices and tools for aluminum spreading, the next action towards excellence depends on understanding the complex spreading process. casting aluminum illinois. The casting process entails a collection of steps that need ability, focus, and precision to detail to make sure exceptional outcomes

Furthermore, putting the liquified light weight aluminum into the mold and mildew should be done gradually and without disruption to avoid air entrapment or incomplete loads. As soon as the light weight aluminum has actually solidified, meticulously getting rid of the spreading from the mold and mildew without try this causing any type of damages is critical. Post-casting procedures such as trimming, fining sand, and finishing should be carried out carefully to accomplish the preferred last item. Understanding each action of the spreading procedure is crucial to creating high-quality aluminum castings.

Advanced Techniques and Tips

Mastering detailed details and implementing innovative techniques can raise the top quality and precision of light weight aluminum spreading processes. One sophisticated strategy is making use of ceramic molds, which offer a smoother surface finish and higher dimensional precision compared to conventional sand molds. Furthermore, utilizing vacuum cleaner spreading methods can assist reduce porosity in the final spreading, causing more powerful and more resilient light weight aluminum components.

Another suggestion is to preheat the mold and mildews prior to putting the liquified aluminum to improve the flowability of the metal and decrease the probability of issues such as cold shuts or misruns. Making use of cool obstructs tactically can assist regulate the solidification price of the light weight aluminum, decreasing inner stress and anxieties and boosting the total mechanical properties of the actors component.

Last but not least, grasping the art of risering and gating is vital for accomplishing sound castings. Properly designed gating risers and systems can aid stop shrinking flaws and guarantee an uniform circulation of steel throughout the mold cavity, bring about premium casting top quality. By including these advanced methods and ideas right into your aluminum casting procedure, you can improve the consistency and accuracy of your final items.

Troubleshooting Common Casting Issues

Addressing typical spreading issues requires an organized strategy to identify and rectify elements affecting the high quality of aluminum spreadings. Furthermore, incorrect mold and mildew dental filling can trigger problems like misruns or cool shuts, resulting in insufficient spreadings. By recognizing these usual spreading troubles and carrying out effective services, aluminum casters can enhance the total top quality and integrity of their castings.

Conclusion

In conclusion, understanding the art of light weight aluminum spreading needs a deep understanding of the history, necessary tools, and advanced techniques entailed in the procedure. By refining your skills and fixing common spreading concerns, you can accomplish exceptional results in your casting jobs. Continuous technique and devotion are essential to enhancing your capacities and producing high-quality light weight aluminum castings.

Mastering each action of the casting procedure is essential to producing top quality aluminum spreadings.

Furthermore, utilizing vacuum spreading techniques can help lower porosity in the final spreading, resulting in more powerful and a lot more resilient light weight aluminum parts.

Addressing usual reference casting concerns needs a systematic strategy to identify and fix elements impacting the top quality of aluminum spreadings. By understanding these typical casting issues and executing effective options, aluminum casters can boost the overall high quality and honesty of their spreadings.

By developing your skills and repairing typical spreading issues, you can accomplish exceptional outcomes in your spreading projects.

Danny Tamberelli Then & Now!

Danny Tamberelli Then & Now! Michelle Pfeiffer Then & Now!

Michelle Pfeiffer Then & Now! Danielle Fishel Then & Now!

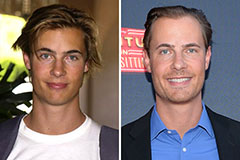

Danielle Fishel Then & Now! Erik von Detten Then & Now!

Erik von Detten Then & Now! Burke Ramsey Then & Now!

Burke Ramsey Then & Now!